The 28th International Workshop on Intelligent Computing in Engineering took place in Berlin from the 30th June until the 2nd July, 2021. Mr Mathias Artus, Mohamed Alabassy and Christian Koch have published their paper "IFC based Framework for Generating, Modeling and Visualizing Spalling Defect Geometries" at this conference. The paper has received the best paper award.

Abstract:

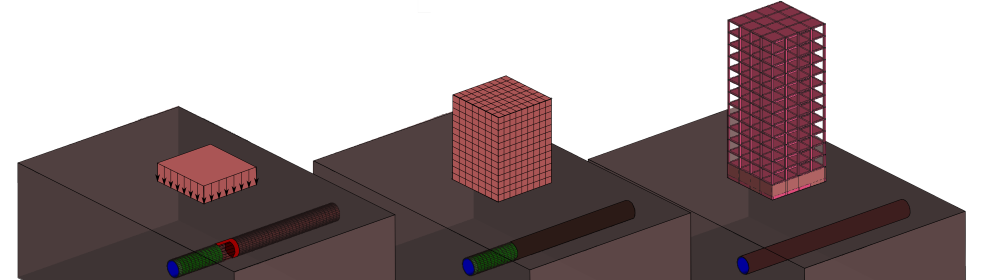

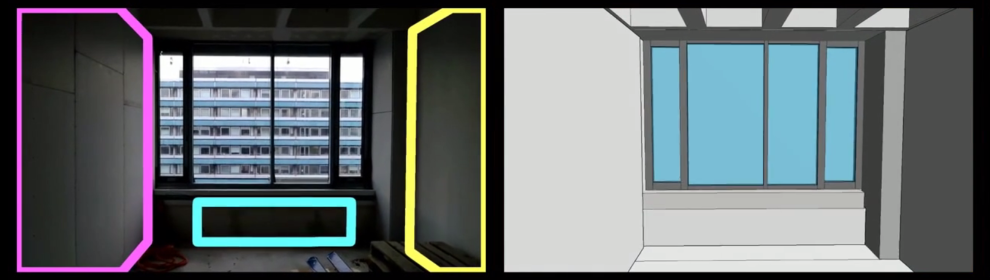

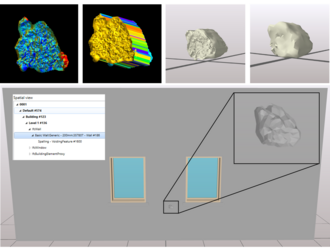

Current traditional bridge inspection practices rely on paper-based data acquisition, its digitization, and multiple conversions in between incompatible formats to facilitate data exchange. This practice is time consuming, error prone, cumbersome, and leads to information loss. One aim for future inspection procedures is to have a fully digitized workflow that achieves loss free data exchange, which lowers costs and offers higher efficiency. Up-to-date, image and depth sensors are increasingly utilized by engineers that could be ground-based or drone-fitted to collect visual inspection data, such as videos or photos. For further processing potentials, like structural analyses, the huge amount of collected visuals needs to be interpreted and transformed into meaningful information. This paper proposes and explains a framework, that creates defect geometries from photos and saves them into an object-oriented data model utilizing the standardized IFC format. Potential strengths to this framework include the automated import of a damaged component into a finite analysis software to support further simulation tasks.

The conference proceedings are in press. The paper can be inquired via mail.