Poor quality is one of the biggest challenges for the construction industry. Most deficiencies occur in the construction process and could be minimized by improved and continuous quality inspections. Therefore, it is necessary to plan -Who?, -When?, -What?,-How? and -Where? a quality inspection has to be done. Preceding literature and software reviews have shown that previous works neglect the planning of quality controls and focus on the recording as well as the evaluation of qualities. Consequently, this research addresses how to improve and automate the planning of quality inspections in construction. Automated planning eliminates monotonous planning tasks, supports inexperienced engineers and enables site managers and supervisors to perform systematized inspections on the construction site.

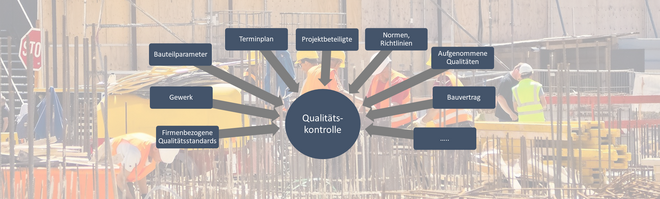

The research uses ontology-based expert systems to describe and plan quality inspections. The description of quality inspections is based on the Ontology for Construction Quality Assurance (OCQA) implemented in OWL as a linked data graph. The automated planning of quality inspections is done by Shapes Constraint Language (SHACL) – Rules. Using these Semantic Web Technologies could enable an extendable, modulized and standardized planning of quality inspections.