Collaborative Research with Partners in Bhutan

Project title:

SusTherm - Scoping study for sustainable thermal insulation of buildings under the alpine climate conditions of Bhutan (Potentialstudie zur nachhaltigen Wärmedämmung von Gebäuden unter den alpinen Klimabedingungen Bhutans)

Funding body:

Federal Ministry of Education and Research (BMBF)

Project duration:

01.02.2015 - 31.12.2016

Principal investigator:

Prof. Dr. Mark Jentsch

Project partners:

Tenzin (director of department) & Karma Namgyel (chief engineer),

Engineering Adaptation and Risk Reduction Division (EARRD),

Department of Engineering Services (DES),

Ministry of Works and Human Settlement (MoWHS)

People involved in the project:

Bauhaus-Universität Weimar: Dipl.-Ing. Christoph Kulle, Dr. Torsten Seiffarth, Dr. Thomas Haupt, Tobias Bode, Toni Pauer

Department of Eneering Services: Tenzin, Karma Namgyel, Karma Euthra, Jamyang Dukjey, Karma Tenzin

Project Outline

Most existing buildings in Bhutan lack thermal insulation and are characterised by high infiltration rates through poorly sealed windows and doors. To improve this situation, the project SusTherm investigated the general feasibility of enhancing air tightness and using thermal insulation materials in Bhutan, looking at solutions that are rooted in the local resource base and know-how.

The project encompassed preliminary building monitoring studies in Bhutan in order to obtain an indication of the current thermal performance of the existing building stock. This was complemented by laboratory work on Bhutanese construction materials in Germany as well as training of Bhutanese early career researchers on the use of building performance assessment equipment. The key focus of this project was to lay the scientific foundations for the development of sustainable thermal insulation materials in Bhutan by establishing, for the first time ever, basic information on the thermal properties of the current building stock.

The outcomes of the research collaboration have been worked up in a journal publication for disseminating the key research findings. In this publication recommendations are being given for thermally improving buildings in Bhutan.

Project Background

In developed countries thermal insulation has been the focus of a large amount of research over the past decades. This could lead to the conclusion that, apart from advanced materials research, there is no scientific need for further investigation. However, this falls short of the reality in developing nations which lack the technical capacity, skills base and financial resources for manufacturing and implementing high end solutions such as mineral wool or polystyrene / polyurethane foam, not to mention the facilities to appropriately dispose off such materials at the end of their useful life. In the setting of a developing country an individual review of the locally available resources and skills base is required in order to produce environmentally, economically and socially viable solutions for thermally improving buildings. This was the starting point of the research collaboration between the Bauhaus-Universität Weimar and the Department of Engineering Services in Thimphu.

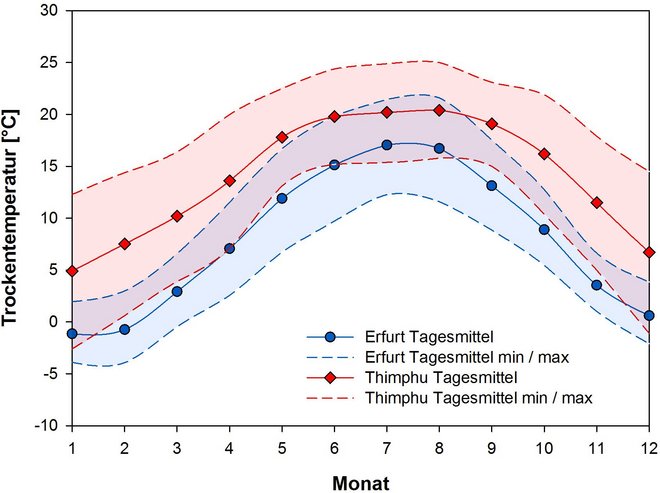

As highlighted by Figure 1 for Paro, Bhutan in comparison to Erfurt, Germany, the western areas of Bhutan experience external winter temperatures at levels that make the consideration of thermal insulation a viable option. Traditionally, buildings in the western parts of Bhutan were constructed of rammed earth and in central and eastern areas of the country with solid stone walls [1]. Over recent decades construction methods in urban areas have changed to uninsulated reinforced concrete frame structures with single brick filling rendered with cement plaster [1,2].

As highlighted in Figures 2 and 3, this shift in construction has resulted in slimmer walls as compared to the traditional construction methods, also losing some of the traditional constructions’ benefits such as thermal mass providing climate moderation on hot sunny days and cool nights [3]. Whilst some research has been conducted examining improvement options for traditional rammed earth constructions in Bhutan to meet modern code of practice standards [3] as well as the seismic performance of modern reinforced concrete frame buildings in Bhutan [4], thermal insulation and air infiltration had, to date, not received any detailed investigations.

The SusTherm project addressed this issue by conducting field study work on the general feasibility of improving airtightness and using thermal insulation materials based on local resources and skills in Bhutan. It has delivered the starting point for the development of more comprehensive research with respect to material development, testing and extended monitoring of case study buildings.

Conducted Work and Results

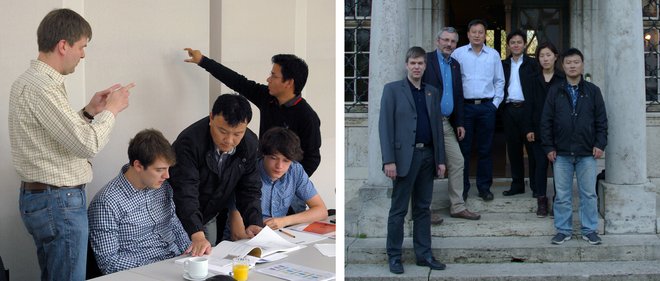

The collaboration between the Bauhaus-Universität Weimar and the Engineering Adaptation and Risk Reduction Division (EARRD) was characterised by joint workshops and an exchange of early career researchers. The first workshop took place in Weimar in April 2015 (Figure 4). It served to develop a catalogue of research questions and to define the requirements for building performance investigations in Bhutan. It was agreed that the main target for the scoping study was to investigate and assess the thermal properties of individual building elements, focussing mainly on walls and windows. Further to this the equipment to be used for the building monitoring in Bhutan was demonstrated and first joint tests conducted in order to familiarise the partners with the devices.

→ more information on the workshop in Weimar (in German)

The second workshop was held in Thimphu, Bhutan in October 2015. This workshop dealt with refining the monitoring programme for the on-site building physics measurements devised at the first workshop in Weimar. Various buildings in the Thimphu area were identified for this purpose, making sure, that a wide range of typical historic and modern construction types were covered, looking at both dwellings and offices. Further to this the workshop included visits to a concrete stabilised earth block production facility and a local window manufacturer.

As part of the workshop the complete team of Bhutanese and German researchers undertook a first joint assessment of a building constructed with cement stabilised earth blocks. This investigation which is shown in Figures 5 to 7 aimed at testing the equipment that was sent from Germany as well as to verify and refine the methods that were devised for the monitoring. Besides looking at wall U-values, the indoor room climate, thermal bridges and capillary water absorption of the walls, airtightness tests were conducted and the properties of building materials, windows and joints of the test buildings documented.

This assessment formed the basis for the building monitoring programme in the month following the workshop which was conducted by the two German MSc students involved in the project and the three Bhutanese early career researchers. Looking at in total 10 different buildings it was shown that both current and historic wall constructions have rather high U-values of typically about 1.0 to 1.5 W/m²K. The air tightness tests revealed that present buildings possess air infiltration rates of up to 5 air changes per hour which is mainly due to poor joints and seals of windows and doors. Furthermore, a room climate moderating effect of historic constructions with rammed earth walls as compared to modern built forms was demonstrated. Overall, the assessments revealed a number of options for improving the quality of the building fabric.

→ more information on the research stay in Bhutan (in German)

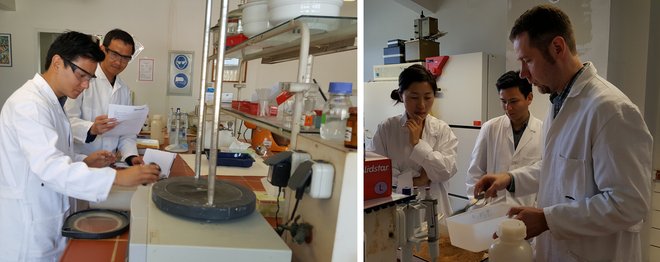

The three Bhutanese early career researchers already involved in the building monitoring programme in Bhutan came to Germany for a two-week research stay in April 2016. In the first week of their stay they conducted further training in the use of airtightness testing equipment as well as thermal transmittance and indoor comfort measurements. This was a preparation for being able to independently conduct such tests in buildings in Bhutan. This was, in the second week, followed by laboratory tests looking at the water absorption, compressive and tensile bending strength and the particle size distribution of Bhutanese cement stabilised earth blocks (CSEB), as these were identified as a centre point of interest for future joint research (Figure 8). The third workshop in Weimar, which followed the research stay of the Bhutanese early career researchers in Germany, served to evaluate the data gathered during the research stays and to prepare the information needed for the joint journal publication given below.

→ more information on the research stay (in German)

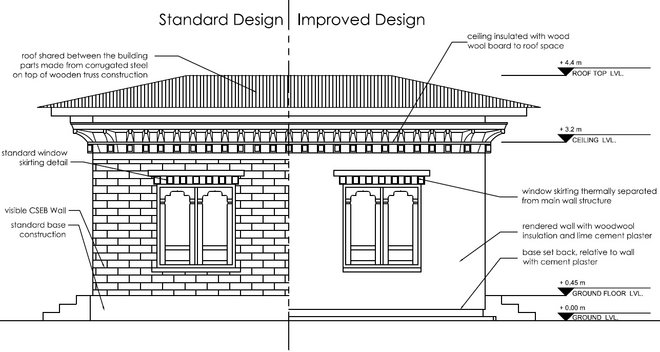

Based on the results of the laboratory tests on cement stabilised earth blocks, that established the potentials for optimising this construction material and the associated construction methods, team member Toni Pauer conducted detailed investigations on this material within his MSc thesis. In climate chamber tests with cement stabilised earth blocks it could be shown that cement stabilised earth blocks with a lime cement plaster on a woodwool insulation would be an effective building skin for the Bhutanese climate conditions (Figure 9). Based on these findings, ideas for an optimised construction method integrating a thermal insulation layer based on locally manufactured woodwoll insulation panels were developed together with the partners from Bhutan as shown in Figure 10. It is hoped that there will be opportunities for testing this on a real demonstration building in Bhutan in future collaborative work.

Published work

Jentsch MF, Kulle C, Bode T, Pauer T, Osburg A, Tenzin, Namgyel K, Euthra K, Dukjey J, Tenzin K. Field study of the building physics properties of common building types in the Inner Himalayan valleys of Bhutan, Energy for Sustainable Development, 38 (2017) 48-66. → view paper

References

[1] Nock D (1995), The Architecture of Bhutan, The Architectural Review, 198 (1186): 78-81.

[2] Lang DH, Sing Y, Namgyel K (2013), Building Classification Scheme for Bhutan, EQRisk project report, Report no. 13–006, Kjeller – Roorkee – Thimphu, August 2013

[3] Sethna Z (2008), A Sustainability Approach to Standards for Rammed Earth Construction in Bhutan, Fourth-year Undergraduate Project, University of Cambridge

[4] Dorji J (2009), Seismic Performance of Brick Infilled RC Frame Structures in Low and Medium Rise Buildings in Bhutan, MSc Thesis, Queensland University of Technology