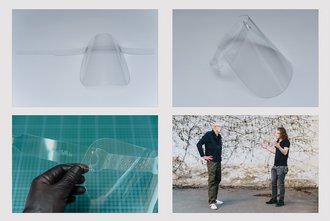

The visor was created as a »friendly gesture« and is designed to help people protect themselves from foreign particles in the air they are breathing. Jason Reizner, Acting Professor of Interface Design at the Bauhaus-Universität Weimar’s Faculty of Art and Design, issued a call at the end of March for people to develop designs for personal hygiene materials and tools: »We have the technology, we have the materials, we have the expertise. So let’s do something«, as Reizner put it. He heads the Bauhaus Form + Function Lab at the Bauhaus-Universität Weimar, which is funded by, among others, the European Union and boasts a state-of-the-art laser cutter that can be used to cut whatever shape is required.

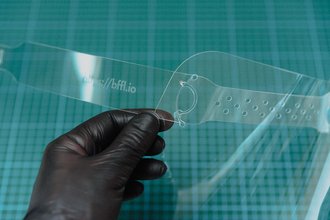

A basic design for a face visor made of PETG film was quicly provided by Andreas Mühlenberend, Professor of Industrial Design, who deals primarily with medical technology. He then worked with Jason Reizner and Kristian Gohlke to further develop the idea. Using rapid prototyping, speedy production of test models and the immediate implementation of improvements, an interdisciplinary design process enabled several prototypes to be made with the laser cutter and various options to be tested and optimised. The team managed to transform the BauhausUniVisor from an idea into a finished product in less than three weeks.

»The BauhausUniVisor needed to be as efficient as possible with its use of materials. It also had to be easy to assemble. The visor is a one-size-fits-all universal design and consists of just two or three parts (depending on the laser cutter used) that are slotted together«, Mühlenberend explains. »This means that the visor can be adjusted to fit any head shape, making it both comfortable and practical«. In keeping with the traditional Bauhaus way of thinking, this is more than just a design for everyone--the design also reflects the university’s aspiration to respond to contemporary issues using modern means, and the visor provides an answer to a current problem.

Wearing facial protection may be an unfamiliar experience for some, and the design may look rather futuristic, but the benefits of the BauhausUniVisor are clear. Since no 3D-printed parts or additional rubber straps are required, production is quick: eight samples can be cut in just five minutes. Initial testing has shown that the material copes well with being cleaned using standard disinfectants; the only downside is that the film is not heat-resistant. The face visor is extremely light--just 60 grams, easily adjusts to fit a variety of head sizes, and can be worn with all hairstyles. Mühlenberend emphasises: »You can wear it over glasses, a hat and of course a respiratory mask. We have also learned that some patients do not like being unable to see the face of the person they are speaking to. Our BauhausUniVisor at least partially solves this problem«.

The list of customers for the BauhausUniVisor is already long: »Our partners, in particular care service providers in the Weimar region, are very interested in having large quantities delivered in a short time frame. However, we also want to reach other systematically important institutions such as businesses, doctors or dentists«, Reizner explains.

Those interested in the friendly gesture that is the BauhausUniVisor can even put the design to private use: it is available as an open design under a creative commons licence. This means that the design and assembly instructions are available for use by the general public provided that the copyright holder and source are stated, and can be used for non-commercial purposes by anyone with a laser cutter. The product designers at the Bauhaus-Universität Weimar have even thought about the fact that not everyone has access to large laser cutter: »We also have a three-piece design with a different strap that allows the visor to be made using a laser cutter that works with smaller cut sizes and pieces of film«, Mühlenberend explains.

The team, lead by Acting Prof. Jason Reizner and Prof. Andreas Mühlenberend, would like to thank Kristian Gohlke and Darko Velazquez for their invaluable help with the project’s further development, process optimisation and communications.

Information about the initiative, a video, and production data are available on the Bauhaus Form + Function Lab website: bffl.io

The creators expressly encourage industrial manufacturers, fab lab and makerspace operators to get in touch:

Prof. Andreas Mühlenberend

Professorship of Industrial Design

Geschwister-Scholl-Straße 7, room 108

99423 Weimar

Tel: +49 (0) 3643 / 58 33 87

E-mail: andreas.muehlenberend[at]uni-weimar.de

Acting Prof. Jason M. Reizner

Professorship of Interface Design

Marienstrasse 5, room 105

99423 Weimar

Tel: +49 (0) 3643 / 58 37 63

E-mail: jason.reizner[at]uni-weimar.de