Original: Naef, M. & Boyd, C. (2008). Feasibility of the Living Canvas – Restricting Projection to a Performer on Stage. Proceedings of the 16th ACM international conference on Multimedia, p. 589-598

Authors: Martin Naef, Cathie Boyd

Keywords: Projection systems, dynamic projection surface, virtual costumes

Summary: The idea for the living canvas is to capture the posture, silhouette and position of the actor and then use that as a projection along with a canvas as a stage background. For the reaction was divided into two area: the technical feasibility and the cooperation with stakeholders persons (such as actor, director). The developers of the living canvas presented as other future projects, so that they many new developed and evaluated.

Main Contents: In the paper the test environments and their results will be described in great detail. Here are just detailed information on stage and clothing, as they are for our interactive costumes most interesting.

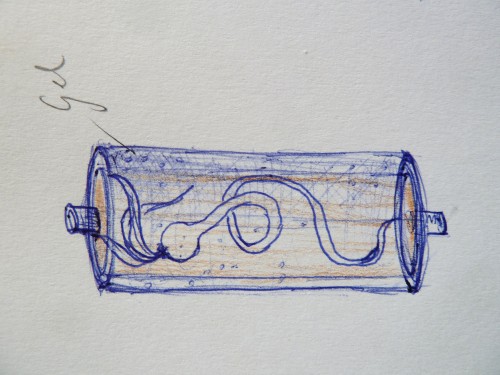

Stage: It is so described that it consists of a regular projection screen and the actor is positioned in front of it. The technique for recording and projection will be installed in front of the stage. For the development was first worked on a small stage model with dolls as a performer on a table. Next, a laboratory environment has been created. This one had original size and could make calibrations.

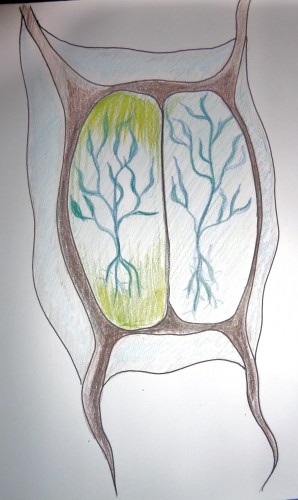

Clothes: In this environment, they also tested various garments and fabrics, to see if they are suitable and how they look in the projected state. The clothes of the actor should preferably be diffuse pattern and no strong highlights to clearly reveal the silhouette, so you can well separate it from the background. The materials used should be matte white so that highlights are minimized. Different substances were illuminated, to see which is the best. Velvet was one of thefavorite. There are fewlimitations onthe design.

In order to develop the system, so that it can be used on a right theater stage, was the next step to test it with real actors. This was done in a week-long workshop in Glasgow. So the criteria of the developers could be tested under real conditions. There were mixed opinions of the people. At next followed more experiments, to get the system ready for a theater production.

Ideas for costume evaluation: The paper employ with costume, stage, lighting and much more, so that we can orient only on parts. In view of our evaluation, the idea is very good, only in scale and then to work in original size, so can errors discovered in small size. The many different tests and their approach (e.g. for the fabric) very interesting for us. Also the test in a workshop with the people who have to work with it later.