Pelton John - the 3D-printed Pelton turbine

Firstly, it should be mentioned that the name came about purely by chance and has no semantic reference to the artist from London!

Objective

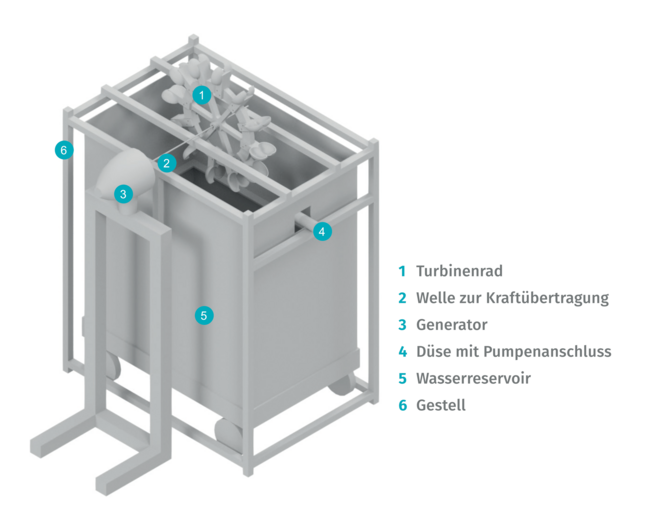

The aim of the project was to develop a hydropower plant with a Pelton turbine that can be used in mountainous regions that have so far had little access to electricity. The less developed, rural regions of Bhutan in South Asia were to serve as an exemplary target area. The low-tech approach took centre stage. The aim was to plan, design and implement in a resource- and cost-optimised manner. The use of additive manufacturing processes such as fused layer modelling enables flexible design and reproducibility.

A practical presentation of the overall system at summaery, the university's annual exhibition of work, was the project's objective and examination achievement.

Challenges

The project involved going through the entire design process of a hydropower plant. From the determination of the technically utilisable hydropower potential to the design and dimensioning of the turbine through to the construction and testing of an overall system.

In addition, the (micro) hydropower plant should be designed as simply as possible to enable easy replication and subsequent adjustments. The design of the housing was therefore also based on an open, spacious structure made of aluminium profiles, which allows a high degree of flexibility. The materials and components used, e.g. bearings, were designed with simple availability and low costs in mind.

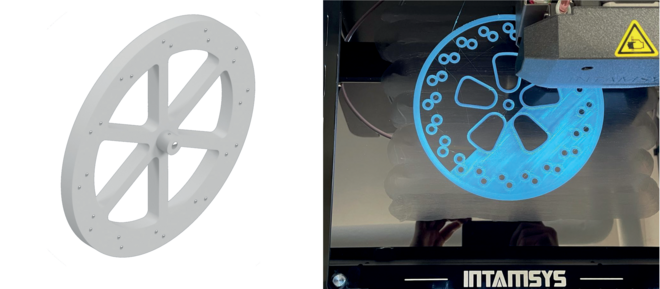

The turbine blades, which are exposed to a flow of around 1500 litres of water per hour at 4 bar, are subjected to the greatest stress. Nevertheless, a conscious decision was made to use a simple material (in this case polylactide - PLA) in order to be able to recognise possible signs of wear after a short period of use. For longer-term use, higher-performance thermoplastics or carbon fibre-reinforced plastics would be recommended.

Implementation in practice

The design was initially planned in the CAD system Inventor following previous calculations. The design of the turbine blades and the blade wheel were iterative processes. Geometries had to be adapted in terms of compressibility and rigidity. The shaft-hub connection also posed a challenge, as a connection using wedges or adhesives was ruled out. A friction-locked connection, which can be easily released again, was realised using clamping rings and pins.

The turbine wheel is surrounded by a transparent housing so that the deflection of the drive jet can be observed and the rebounding water can be channelled into the collecting basin below. This allows the water to be pumped in a circle to the drive. After initial practical tests, the experimental setup was optimised to minimise water losses.

A permanent magnet ring generator from a small wind turbine serves as the generator. The three-phase alternating current from the generator is rectified and temporarily stored in an accumulator via a DC/DC converter with charging electronics. During the practical presentation at summaery, the electricity generated was used to drive an effective advertising bubble machine.