Holistic heat supply solution with H2

Project title:

energy4CHP - CO2-neutral energy supply in energy-intensive commercial enterprises - hydrogen-based sector integration in the provision of heat and electricity

Funding body:

Federal Ministry of Research, Technology and Space (BMFTR)

Project duration:

01.06.2023 – 31.12.2025

Principal investigator of the project:

Prof. Dr. Mark Jentsch

Project partners:

The WIR! alliance partner Wissenschaftlich-Technisches Zentrum für Motoren- und Maschinenforschung Roßlau gGmbH is involved in the project alongside the Chair of Energy Systems at Bauhaus-Universität Weimar. Hyrican Informationssysteme AG is an associated partner.

Team members involved in the project:

Artjom Kolwa M.Sc., Dipl.-Ing. Christian Gebhardt-Scholz, Benjamin Breuer M.Sc., Kaspar Schmädicke B. Sc., Nicole Meyer M. Sc.

Project outline

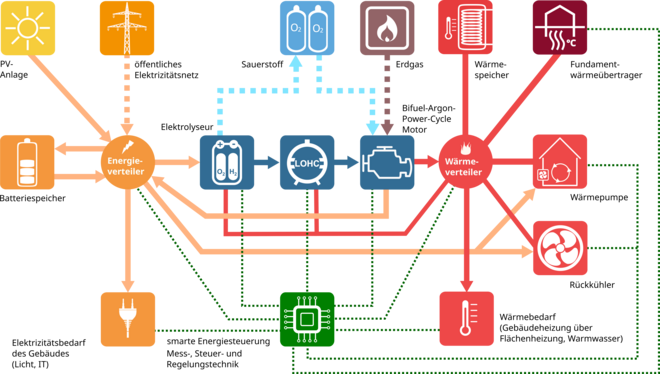

As part of the research project, a novel system for CO2-neutral energy supply to commercial enterprises is being developed, implemented and tested. This system for combined electricity and heat supply is housed in the so-called Energy Station, a demonstration building at the project partner WTZ Roßlau gGmbH.

The system combines five main components: an electrolysis plant for H2 production and a bifuel combined heat and power plant (CHP) that can be operated with both natural gas and hydrogen, a photovoltaic system, a hydrogen storage infrastructure and a foundation heat exchanger with a heat pump

A newly designed intelligent heat distribution network (thermodynamic switch) is used to optimally connect individual heat sources and sinks. Figure 1 summarises the concept of the energy4CHP project.

The Chair of Energy Systems at the Bauhaus University Weimar is responsible for the following project contents in the project:

Thermodynamic switch (multivalent heating network)

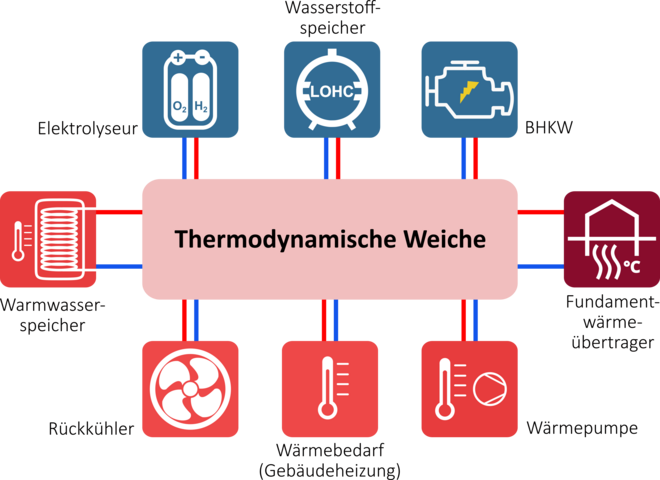

A hybrid heating system consisting of a large number of heat sources and sinks requires dynamic adaptation to changing conditions, e.g. in the supply of environmental heat (e.g. from the air or the ground). For optimal redistribution of thermal energy (heat), a multidimensional heat distribution network, known as a Thermodynamic switch, can be used.

Such a multivalent network consists of a large number of nodes, each of which performs a specific distribution function. Within the multivalent heat network, parallel fluid circuits can thus be formed and directed in a targeted manner. The optimum path is determined depending on the available temperatures and outputs. This allows different types of heat sources and sinks to be interconnected in a targeted and dynamic manner (see Fig. 2).

Foundation heat exchangersCommercial enterprises are often characterized by contaminated soils due to historical reasons. The use of geothermal heat (e.g. through geothermal probes) is therefore heavily regulated at such locations. For this reason, an innovative foundation heat exchanger was developed and implemented for the input and extraction of heat in near-surface soil layers (see Fig. 3).

The foundation heat exchanger is not thermally separated from the underlying ground, which is why the (total) heat storage capacity is greater than that of the pure component. The component was largely thermally decoupled from the sides and top using thermal insulation panels.

The component, measuring 10 x 2.5 x 0.3 meters, was constructed by the project partner at the end of 2024 (see Fig. 4).

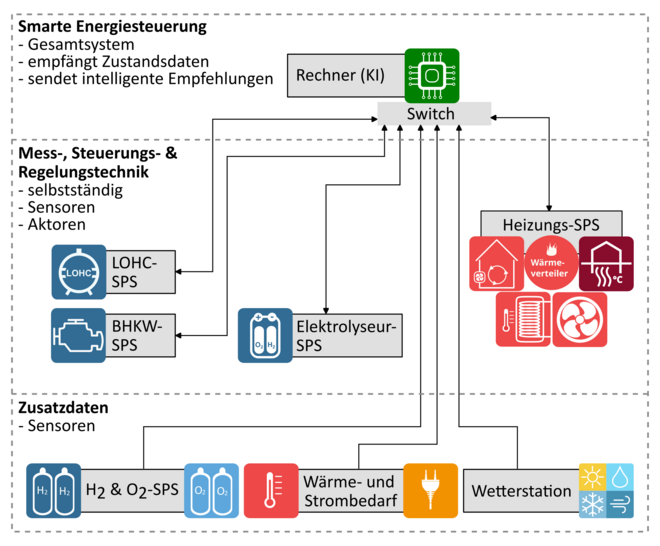

Intelligent control

The entire system is monitored and controlled using a programmable logic controller (PLC). The process measurement values read and evaluated by the PLC are bundled and transmitted to a higher-level data management and control system via appropriate communication protocols. In addition, data is exchanged with a weather station and the other components of the overall heat supply system (e.g. CHP unit, electrolyser, etc.). Based on the measurement data received, the respective operating scenarios are evaluated as a result of an implemented intelligent control logic.

Outlook

The commissioning of the first system components – such as heat pumps, storage, and distribution systems – is planned for the 3rd quarter of 2025. The goal of the research project energy4CHP is to demonstrate to what extent climate-neutral energy supply can be implemented in practice for industry and research.