goal

The aim of this experiment was to understand the possibilities of using mycelium as a biodegradable material, and to explore its strengths and weaknesses, especially in a combination with straw. The main goal was to see how these two materials work together regarding growing intensity, strength, and appearance.

workshop

During the workshop, Alessandro Volpato introduced us to special living organisms, such as algae, slime mold or mushrooms that glow in the dark. Taking into account the habitus, place of occurrence and ability of these organisms, we were given the task of developing ideas for a product as a group, in a start-up manner, which are made using the organisms we have studied and offer a solution to an everyday problem.

As a start, we prepared argar, which is the initial substrate of the step-by-step mycelium growth process, which was followed by rye.

preparing the mixtures

3 different substrate mixtures were produced. On the one hand, the already tried-and-tested recipe with hemp, on the other hand, only with straw, and finally, the two together.

manufacturing progress

The production of the mycelium brick in a nutshell, the already existing fungal threads are mixed with a larger volume of substrate, and then allowed to multiply on it until it is ready for another transplant.

growing together

An important element of our experiment is growing together, so the separate elements will be temporarily attached to each other with a wooden toothpick, until their surface and the inner parts are uniformly grown together.

stopping the growth process

Drying is a very important step, as the element can lose up to 60% of its weight in the process, it prevents possible contamination, and the growth process of the fungus stops and is deactivated.

analysis

Depending on the compaction, the internal composition of the elements is homogeneous and solid after drying. Its surface is mostly uniform, ivory-colored and soft, but in some places brownish color transitions may occur. The weight of the final building element varies depending on the density, which is only 550g for straw and 1050g for hemp.

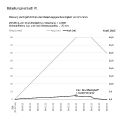

compressive strength testing

The compressive strength test was essential for the purpose of assessing the further usability of the block in the construction industry.

mycelium growth phases on rye substrate

uncontrolled growth on rye substrate

organic shapes

The main goal of the side experiment was to observe that we can create these organic forms with alternative formwork. We used nylon stockings and cellophane to help with this and observed that the same mixture of mycelium and substrate reacted in completely different ways to the different formworks.

foreign objects

The main goal of the second side experiment was to observe whether the mycelium attacks organic materials other than the substrate, such as MDF or solid wood. Since our research mainly focused on reforming the construction industry, it was important that the added material to be tested was not sterilized, similar to an environment outside the laboratory. We observed that the mycelium began to spread on the surface of the solid wood, where as a result of the wet environment, other molds also began to grow.

exhibition

go4spring 2023

conclusion

Including several experimental directions, the project aimed to learn about and exploit the potential inherent in the use of mycelium in the construction industry.

First, to replace the already widely used substrate for the growth of mycelium, the mixture of hemp, wheat bran, water and gypsum, with a simpler and cheaper material, with straw. We wanted to see if the growth can be just as successful with fewer measurements, and ingredients, therefore stepping out from the lab would be possible in the future. According to our observations, the mycelium grew just as quickly and intensively on the straw, compared to the mixture just mentioned, and no significant difference could be observed on the exterior of the finished objects either.

On the other hand, the mushroom threads formed a close connection between the elements placed next to each other and joined together. It is well proven that even after the 40% size reduction of the test cubes that occurred during the pressure tests, it didn't start to separate where the elements were joined.

During the pressure tests, the compressive strength of the test cubes of each mixture was revealed. A significant difference is that the general substrate, i.e. the mixture consisting of four materials, can carry almost twice as much load as straw alone. This is due to the larger particle size of the straw and its natural tubular design, as a result of which a lower density was achieved, which also greatly affected the compressive strength. If the straw is ground to a smaller size, it could certainly compete with the density of the one made with hemp.