| Line 22: | Line 22: | ||

|24.10.2024 | |24.10.2024 | ||

|Planted chia seeds on cotton. | |Planted chia seeds on cotton. | ||

|[[File:20241024 Chia seeds.jpg|none|thumb| | |[[File:20241024 Chia seeds.jpg|none|thumb|75x75px]][[File:20241024 Chia seeds bag.jpg|none|thumb|99x99px]] | ||

|- | |- | ||

|25.10.2024 | |25.10.2024 | ||

Revision as of 12:01, 16 February 2025

Respiring Reflections

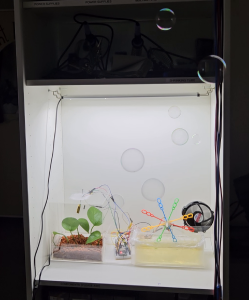

This project is called "Respiring Reflections", a bubble machine which is connected to Pothos plants (Epipremnum aureum) in an enclosed environment. Read below to follow the process and the story behind the making of this project.

//TODO: add gif/video

First Experiments

In the beginning of our semester, we were given some seeds to be grown at home. This was our first experiments for this class. I was growing Chia seeds (and also apple seeds that didn't really grow into anything) on a piece of cotton and inside a plastic bag. I have not done this since school time, so it was interesting and fun. During our first experiments in growing seeds, we documented our plants' progress. I documented it in form of pictures and diary entries. Other than the Chia seeds, I also grew Pothos plants (Epipremnum aureum) from cuttings.

Chia seeds

//TODO: add pics

| Date | Note | Image(s) |

|---|---|---|

| 24.10.2024 | Planted chia seeds on cotton. | |

| 25.10.2024 | Start sprouting. | |

| 26.10.2024 | Grow more at night, more sprouting (first green leaf buds can be seen). Some drops of water added. | |

Pothos cuttings (Epipremnum aureum), Jade variation; Pearls & Jade variation

Jade variation: green-colored leaves; Pearls & Jade variation: green and white pattern leaves

//TODO: add pics + examples of diary entries

Motivation

After attending a few sessions of this class, I started brainstorming what could my topic of interest be. Honestly it was a bit confusing and challenging to try combining/connecting plants and electronics somehow. Before this bubble machine idea came up, I had some more ideas and sketched them in my notebook. In the end, I was interested in the respiration process of my plants and decided to make a bubble machine which can visualize the respiration process/cycle of my plants. I think bubbles are fun and matches the concept of respiration, since they are somewhat transparent/translucent, and we cannot really observe the plants' respiration. With the bubbles, I was trying to simulate or reflect the respiration, hence the project name "Respiring Reflections".

//TODO: add initial sketches

Before the bubble machine idea, I already decided to grow Pothos plants (Epipremnum aureum) from cuttings (Stecklinge) and documented their growth. During the process, that was where I started to think: "Are my plants breathing? They seem fine, their leaves are green... but are they really okay?" The idea was that the soap bubbles quantity would be according to the CO2 level of the plants' enclosed environment, divided into three categories: Low, Medium and High CO2 level. When the CO2 level in the plants' environment rises, then there will be more soap bubbles. In order to do so, I watched videos and read blogs/forums related to the DIY bubble maker machine, until I had a plan on the materials needed and how to make it.

You can find my initial project mood board here: https://miro.com/app/board/uXjVLBm7F8w=/?share_link_id=117991010729

Materials

- ESP32

- Breadboard (half-size)

- CO2 sensor MH-Z19C

- Stepper motor 28BYJ-48

- Stepper motor driver module ULN2003

- PWM fan AMD Ryzen 7 1700

- 10kΩ resistor

- Power supply 12 volts

- Buck converter 12 volts to 5 volts

- Acrylic sheets

- Bubble sticks

- Soap bubble liquid

- Lots of cables...

//TODO: add pics of materials

Wiring Diagram

During the process of making the bubble machine, unfortunately I fried my ESP32... I'm still not sure why, but perhaps it was due to false wiring. Thus I made this wiring diagram so that the wiring could be clear. I tried some free tools to make wiring diagram, such as but in the end I stick with EasyEDA to make this. The wiring diagram helps me a lot in reproducing the wiring I wanted to do, as well as to ask opinion from Christian or someone else for consultation.

Since I wanted this installation to be a standalone one, I powered the ESP32 with the power suppy of 12 volts, through a buck converter of 5 volts, 1 Ampere. For this, I went to an electronics store in Erfurt (Bastlerland) and showed my wiring diagram for this project. The guy in that store recommended me this solution and I followed it.

Codes

To program the ESP32, I used Visual Studio Code with PlatformIO extension. Here are the codes I uploaded to the ESP32 to run the bubble machine:

Bubble machine

main.cpp:

#include <Arduino.h>

#include <AccelStepper.h> // Load the AccelStepper library

#include "MHZ19.h"

#include <HardwareSerial.h>

#define motorPin1 12 // IN1 pin on the ULN2003 driver

#define motorPin2 14 // IN2 pin on the ULN2003 driver

#define motorPin3 27 // IN3 pin on the ULN2003 driver

#define motorPin4 26 // IN4 pin on the ULN2003 driver

AccelStepper stepper(AccelStepper::HALF4WIRE, motorPin1, motorPin3, motorPin2, motorPin4);

#define BAUDRATE 9600

/*CO2 sensor*/

#define RX_PIN 16 //wire green here (8)

#define TX_PIN 17 //wire blue here (9)

/*CO2 sensor variables*/

MHZ19 myMHZ19;

HardwareSerial mySerial(2);

unsigned long getDataTimer = 0;

void verifyRange(int range);

int CO2;

int8_t Temp;

int currentCategory = -1; // To store the current CO2 category

int newCategory;

void setup() {

// put your setup code here, to run once:

Serial.begin(9600); // initialize the serial monitor

stepper.setMaxSpeed(1000.0); // set the max motor speed

stepper.setSpeed(100); // set the current speed/initial speed

mySerial.begin(BAUDRATE); // sensor serial

/*CO2 sensor*/

myMHZ19.begin(mySerial); // pass to library

myMHZ19.autoCalibration();

}

void loop() {

// put your main code here, to run repeatedly:

stepper.runSpeed();

/*CO2 sensor and stepper motor speed logic*/

if (millis() - getDataTimer >= 250) //refresh rate: 250ms

{

//int CO2;

/* note: getCO2() default is command "CO2 Unlimited". This returns the correct CO2 reading even

if below background CO2 levels or above range (useful to validate sensor). You can use the

usual documented command with getCO2(false) */

CO2 = myMHZ19.getCO2(false); // Request CO2 (as ppm)

Serial.print("CO2 (ppm): ");

Serial.println(CO2);

//int8_t Temp;

Temp = myMHZ19.getTemperature(); // Request Temperature (as Celsius)

Serial.print("Temperature (C): ");

Serial.println(Temp);

getDataTimer = millis();

// determine the category of CO2

if (CO2 < 900) { // lower threshold: 900 ppm

newCategory = 0; // Low CO2

} else if (CO2 < 1000) { // higher threshold: 1000 ppm

newCategory = 1; // Medium CO2

} else {

newCategory = 2; // High CO2

}

// switch category if the current category is no longer valid

if (newCategory != currentCategory) {

currentCategory = newCategory;

switch (currentCategory) {

case 0:

stepper.setSpeed(100); // Slowest speed

break;

case 1:

stepper.setSpeed(300); // Medium speed

break;

case 2:

stepper.setSpeed(500); // Fastest speed

break;

}

}

}

}platformio.ini:

[env:esp32dev]

platform = espressif32

board = esp32dev

framework = arduino

lib_deps =

waspinator/AccelStepper@^1.64

wifwaf/MH-Z19@^1.5.4Calibration

To determine the thresholds for my bubble machine, I uploaded a calibration script to the ESP32 and let the CO2 sensor run in the enclosed plants' casing for minutes until the values are somewhat "stable" and not deviating too much from the previous ones:

main.cpp:

#include <Arduino.h>

#include "MHZ19.h"

#include <HardwareSerial.h>

#define BAUDRATE 9600

/*CO2 sensor*/

#define RX_PIN 16 //wire green here (8)

#define TX_PIN 17 //wire blue here (9)

/*CO2 sensor variables*/

MHZ19 myMHZ19;

HardwareSerial mySerial(2);

unsigned long getDataTimer = 0;

unsigned long timeElapse = 0;

void verifyRange(int range);

int CO2;

int8_t Temp;

int minCO2 = 1500; // save min CO2 value

int maxCO2 = 400; // save max CO2 value

int range;

void setup() {

// put your setup code here, to run once:

Serial.begin(9600);

mySerial.begin(BAUDRATE); // sensor serial

/*CO2 sensor*/

myMHZ19.begin(mySerial); // pass to library

myMHZ19.autoCalibration();

timeElapse = 6e5; // wait 10mins to calibrate

Serial.println("Calibrating... (10mins)");

delay(timeElapse);

}

void loop() {

// put your main code here, to run repeatedly:

if (millis() - getDataTimer >= 1000) // Check if interval has elapsed (non-blocking delay() equivalent)

{

CO2 = myMHZ19.getCO2(); // get CO2 value

Serial.print("CO2 (ppm): ");

Serial.println(CO2);

if(CO2 < minCO2){ // if current CO2 value is lower than the min value: save the new value as the min

minCO2 = CO2;

}

if(CO2 > maxCO2){ // if current CO2 value is higher than the max value: save the new value as the max

maxCO2 = CO2;

}

Serial.print("Min CO2: ");

Serial.println(minCO2);

Serial.print("Max CO2: ");

Serial.println(maxCO2);

int8_t Temp; // Buffer for temperature

Temp = myMHZ19.getTemperature(); // Request Temperature (as Celsius)

Serial.print("Temperature (C): ");

Serial.println(Temp);

range = maxCO2 - minCO2; // calculate the range

Serial.print("Range: ");

Serial.println(range);

Serial.print("Lower threshold: ");

Serial.println(minCO2 + (range * 1 / 3)); // lower threshold

Serial.print("Higher threshold: ");

Serial.println(minCO2 + (range * 2 / 3)); // higher threshold

getDataTimer = millis(); // Update interval

}

}platformio.ini:

[env:esp32dev]

platform = espressif32

board = esp32dev

framework = arduino

lib_deps = wifwaf/MH-Z19@^1.5.4Respiring Reflections - First Prototype and First Trials

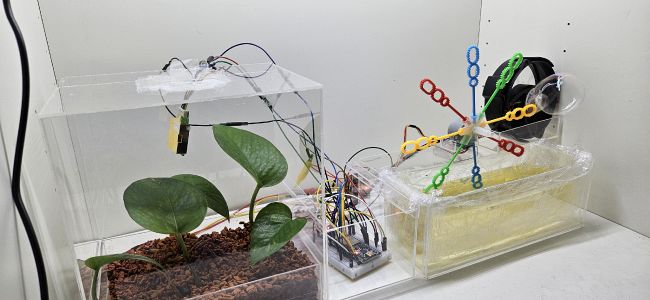

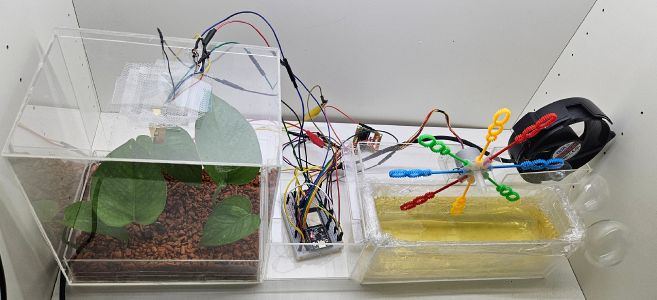

For the bubble machine itself, all I needed was a fan, a rotating motor, bubble sticks and a container for the soap bubble liquid. To produce more soap bubbles, the motor needs to rotate faster. The bubble sticks need to dip into the soap bubble liquid and then they will pick up the soap liquid to be blown in front of a fan to produce bubbles. To test out this logic, I made the first prototype out of cardboard. This turned out to be helpful for consideration of measurements for the final prototype. Other than the bubble machine as a whole, I also did trials on the CO2 sensor in the plants' enclosed environment and to determine the closeness of the bubble sticks to the fan to produce the bubbles. Through the trials, I found that the fan was strong enough to blow the bubbles only in specific areas, with a certain closeness. Therefore, I needed to consider and experiment with the distance and placement of the fan towards the rotating bubble sticks.

//TODO: add pics of cardboard prototype + trials

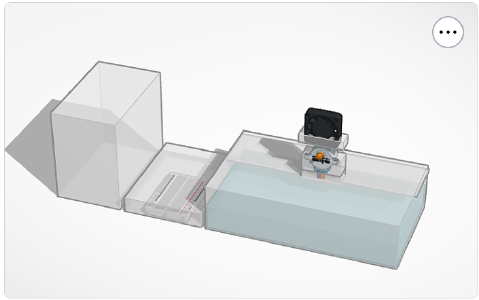

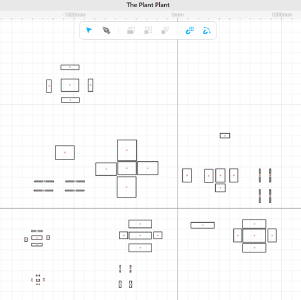

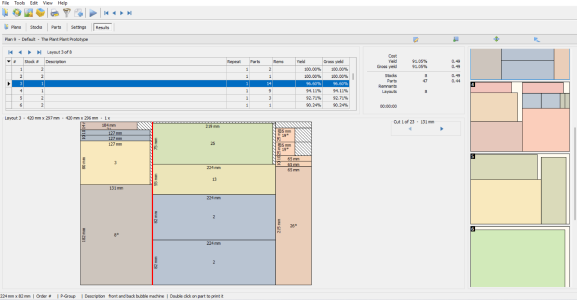

Respiring Reflections - Final Prototype (Winterwerkschau)

To build the final prototype for the Winterwerkschau, I decided to change the casing material to transparent acrylic sheets. I think it matches the concept that everything is transparent/translucent. Before building the real physical final prototype, I tried out several online tools to help me, such as 3D sketch plan, 2D blueprint and optimization software to cut the acrylic sheets, to know how much materials I needed. Because the dimension of my final prototype will depend on the bubble sticks (attached to the rotating stepper motor), and also the length of the breadboard, I decided to use half-size breadboard instead of a full-size one, since the full-size will be redundant for my project. The wiring diagram helped me to consider this, since I wouldn't need that much space of the breadboard. The half-size breadboard minimized the length (or depth) dimension of my prototype a lot. In building the final prototype, I learned a lot how to be creative in finding solutions with common materials or tools that I could find in the lab (either diyElectronics Lab in B15 or Electronics Lab in M5), at home or in the city. I'm glad that I made it work in the end:)

//TODO: add pics + gif/video

Self-reflection and Lessons Learned

This semester I got a chance to experience what it feels like to be a student under Art and Design Faculty at Bauhaus University Weimar. This is not a class I usually take, but I had fun, although it could be stressful, challenging and confusing at times. I wasn't familiar at all with the artistic approach, I felt a little bit out of place since I was the only one not from the Art and Design Faculty. But Christian, Klaus and everyone in the class were really helpful and always had interesting ideas or suggestions every session. I felt really supported from beginning to the end.

Prototyping hurdles

Technically it was challenging, since it was the first time I learned ESP32, plus I broke my first one in this class... But lessons learned, always make a wiring diagram and triple check everything! I usually only deal with digital problems, so prototyping with electronics and physical mechanical things adds dimension in the project, which means when I encounter a problem, that problem could be in any dimension and I couldn't really pinpoint where. Throughout the class, I experienced that problems can arise everywhere: cables, ESP32, understanding of mechanical/physical things, materials, tools, device specification that needs specific usage in the code, etc. But that's just the art of prototyping, as my friend said. We're not doing a finished line of production, so enjoy the ups and downs, the successes and failures. Fail fast is also better.

I feel like I spent most of my time designing and planning for my prototypes rather than building the prototypes, both for the cardboard prototype (first prototype) and also the final one. I wasn't sure how it was supposed to be made, but I kept thinking about the measurements and the mechanisms so that I could make them work, at least logically in my mind. Sometimes even night and day, that I got a little bit overwhelmed. In the end though, I compromised the accuracy aspect and focused more on the functionality/mechanical things to make it work. "Just try it out" was definitely a motto for this project.

Learning from my Pothos plants (and observations)

In this class, this is the first time I grew Pothos plants from cuttings as a part of my experiment. I learned resilience and adaptability from them, especially from the Jade variation. They are so resilient, and they all survived winter. In contrary, only one of the Pearls & Jade variation survived until now, but I learned that for Pearls & Jade variation, they should be propagated in a few leaves as a group instead of single leaves. This should increase their survival chances. Another observation is that, because I propagated them in 2 different mediums (water and Seramis medium), the roots that grew depend on the medium. The roots in water propagation grew smooth as one long root, whereas those in Seramis medium were branched and tend to grow deeper into the Seramis medium. It reminds me that adaptability is an important survival trait.

Future Work

If I had to think about this project and relate it to my study program, I would have difficulties. I'm not exactly experienced in speculative design, and perhaps I'm not interested in that area in the future as well, but who knows. However, it might be a bit far-fetched, but I could imagine my bubble machine as an outdoor "smart home system" that visualizes the respiration of houseplants, since indoor can be messy. Bubbles can be fun to look at, especially for children. During the Winterwerkschau, I enjoyed witnessing that people of all ages enjoying the bubbles, but especially children. Some of my friends also reported this to me and it was heartwarming. And maybe add some indicators, to indicate if something goes wrong with the plants (so that the owner(s) can check). This idea can be elaborated further, which indicator(s) can be used, what kind of thresholds, what indicates "healthy" and "sick" plants, etc. A mechanism that could be added would be to refill the soap liquid from time to time (during Winterwerkschau I did it manually).

Gallery

The Plant Plant Gallery (Nextcloud Bauhaus Uni), Password: theplantplant (CO2 sensor first trial pictures are inside)

References

CO2 sensor MH-Z19C

- https://www.neumueller.com/datenblatt/neumueller/MH-Z19C.pdf (Datasheet)

- https://randomnerdtutorials.com/esp32-uart-communication-serial-arduino/ (Concept, wiring, code)

PWM fan AMD Ryzen 7 1700

- Arduino Fan Control using High Frequency 25kHz PWM // 4-Wire CPU Fans - YouTube (Concept, wiring, code); adapted to ESP32

Stepper motor 28BYJ-48 and stepper motor driver module ULN2003

- https://randomnerdtutorials.com/esp8266-nodemcu-stepper-motor-28byj-48-uln2003/ (Concept, wiring, code); adapted to own implementation