From a Dream to a Project: The Bauhaus-Universität Weimar Kreativfonds

Masks used as protection against the coronavirus have produced millions of tonnes of plastic waste. What if this waste could be recycled, even those masks contaminated by the virus? Two Bauhaus-Universität Weimar students could not stop asking themselves this question. Using a 3D printer, they showed what would be possible and created a toothbrush using recycled mask material. Their work is currently on display at the Marta Herford Museum or Art, Architecture, Design.

Episode 1: From Protection to Plaster —FFP2 Masks Become Toothbrushes

Friedrich Gerlach und Felix Stockhausen explain how they came up with the idea in their workshop. Located in a former carpentry workshop, the workshop is attached to a turn-of-the-century villa. Doubling as a shared flat, the villa houses a workshop where students experiment with wood, ceramics, lacquers and 3D printing. Every square inch of the six rooms is filled with wood, prototypes, tools, tables and machines. »It’s a bit chaotic in here«, says Gerlach apologetically.

He and his classmate are studying Produktdesign (Product Design) in the Faculty of Art and Design. Together they observed to following during the coronavirus pandemic: Used only for a short time, masks quickly become waste, even hazardous waste — something disgusting. On top of this are the rejects from the manufacturers. Without recycling, enormous amounts of plastic waste end up in landfill and in the oceans. It takes an estimated 400 years for the plastic in the masks (polypropylene) to decompose. This problem, the two students say, served as the impetus for their independent project titled »UNclean Plastics«. The goal was not to revolutionize toothbrush production, but to show what is possible: Through recycling and new manufacturing, contaminated waste can in fact be transformed into a hygiene product — a toothbrush.

They began their project in spring 2021. The next step was to find investors and the students applied to the Bauhaus-Universität Weimar Kreativfonds. With the promise of 700 euros, they purchased the necessary materials for printing and safety. They then found more investors. They began work in the workshop. Recycling, however, had its downsides: In addition to polypropylene, most masks are made with metal nosebands and rubber bands for the ears — these have to go. The students removed these parts by hand from the 4000 pieces provided to them by a manufacturer and acquaintances. In photos, Gerlach and Stockhausen wear yellow protective suits and breathing masks. This protective gear was worn at all times when it was unclear here the masks had come from or if they had been contaminated by the virus.

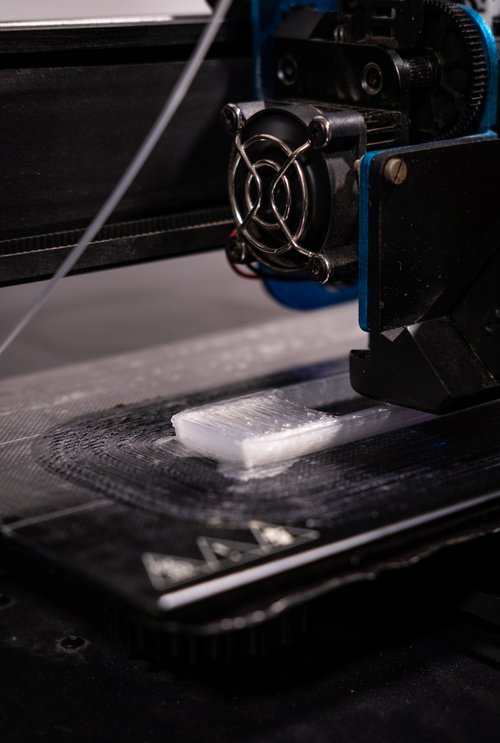

They painstakingly collected polypropylene and melted it at 200 degrees Celcius into sheets that were then broken down into jagged pieces. The heat destroyed any potential viruses. Stockhausen points to a see-through bag lying on a workshop table. In its current state, it still looks a bit like dirty snow thanks to its grey-white colour. The pieces will be crushed into small balls, pulled into long threads and wound onto a spool. This will allow the material to be used in a 3D printer, two of which are in a separate room in the villa with a view of the garden. Gerlach bends the plastic between his fingers while Stockhausen explains that, »Polypropylene has a lot of positive properties; it’s light, durable and extremely flexible.« The material that the masks are made of, he says, is a versatile, complex material.

They mixed recycled fibres with new polypropylene as a test. The result? Working with purely recycled granules is feasible, but less convenient. After creating initial simple forms, such as a small vase, Gerlach and Stockhausen tackled the toothbrush. The toothbrush should be created from a single material and in one piece. For this purpose, two toothbrushes were printed at the same time and joined together back to front to form a block. The fine bristles needed to be supported by brush heads on both sides. After printing, the two toothbrushes were separated. By doing this, the students were able to create both a rigid solid form —the handle of the toothbrush— and a flexible form—the bristles. Anyone who picks up the toothbrush is surprised a how lightweight it is and that it is actually functional.

At one point in time, the two product designers thought that they would have to hurry with their project and that the pandemic would soon be over. But their topic remained relevant. It is unsurprising, therefore, that the students regularly receive requests to pick up masks for recycling. Many have taken notice of the project thanks to »UNclean Plastics« being shown in the Thuringian parliament and at an international trade show, Elmia Subcontractor Jönköping, in Sweden, among other places. The project was also recently recognised by the tenth Marta Herford RecyclingDesignprize. The Stadtwerke Weimar has also recognised the students’ work.

For the time being, the plan is to stop tinkering with masks. Both developers have moved on and are pursuing new projects. Gerlach is finishing up his Bachelor’s degree, working on bacteria and cement. Stockhausen will soon begin his Bachelor’s thesis and hopes to devote his time to bicycle transport in local traffic. Finding alternative, sustainable uses for resources will therefore continue to keep them busy.

For further information, visit:

https://www.friedrichgerlach.de/unclean-plastics and https://www.felixstockhausen.de/unclean-plastics

About the Bauhaus-Universität Weimar Kreativfonds

Shooting a short film, exhibiting a photo series, designing a new product — creative minds are always coming up with exciting new ideas. But what can they do if they don’t have the funds? For nearly 15 years, the answer to this has been the Bauhaus-Universität Weimar: It’s worth it to apply to the Kreativfonds! Professors, scientific employees, doctoral candidates and students from all faculties can apply up to twice a year. The next deadline is 15 September 2022.

Who can receive support?

Artistic and creative projects with no set format. The determining factors are an innovative idea and a plan to realise it. Students and doctoral candidates must include a letter of recommendation with their application.

Find out more on the Kreativfonds here:

https://www.uni-weimar.de/de/universitaet/forschung-und-kunst/foerdermoeglichkeiten/forschungsfoerderung/uni-interne-foerdermoeglichkeiten/kreativfonds/

Projects from 10 years of Kreativfonds:

https://www.uni-weimar.de/de/universitaet/forschung-und-kunst/foerdermoeglichkeiten/forschungsfoerderung/uni-interne-foerdermoeglichkeiten/kreativfonds/ausstellung-10-jahre-kreativfonds/

For information on the Kreativfonds, contact Kristina Hellmann, Research Operations Office, by telephone +49 (0) 36 43 / 58 25 39 or per E-mail at kristina.hellmann[at]uni-weimar.de.

If you have any questions about the article, contact Dr. Stefanie Waske, Science Editor, by telephone +49 (0) 36 43 / 58 11 24 or per E-mail at stefanie.waske[at]uni-weimar.de.